Advanced Power Line Coatings

SE RANGE- FUNCTIONAL POWER LINE COATINGS BY ASSETCOOL

SURFACE ENGINEERING (SE) OF OVERHEAD CONDUCTORS FOR OPTIMAL PERFORMANCE, EFFICIENCY, NOISE AND DURABILITY

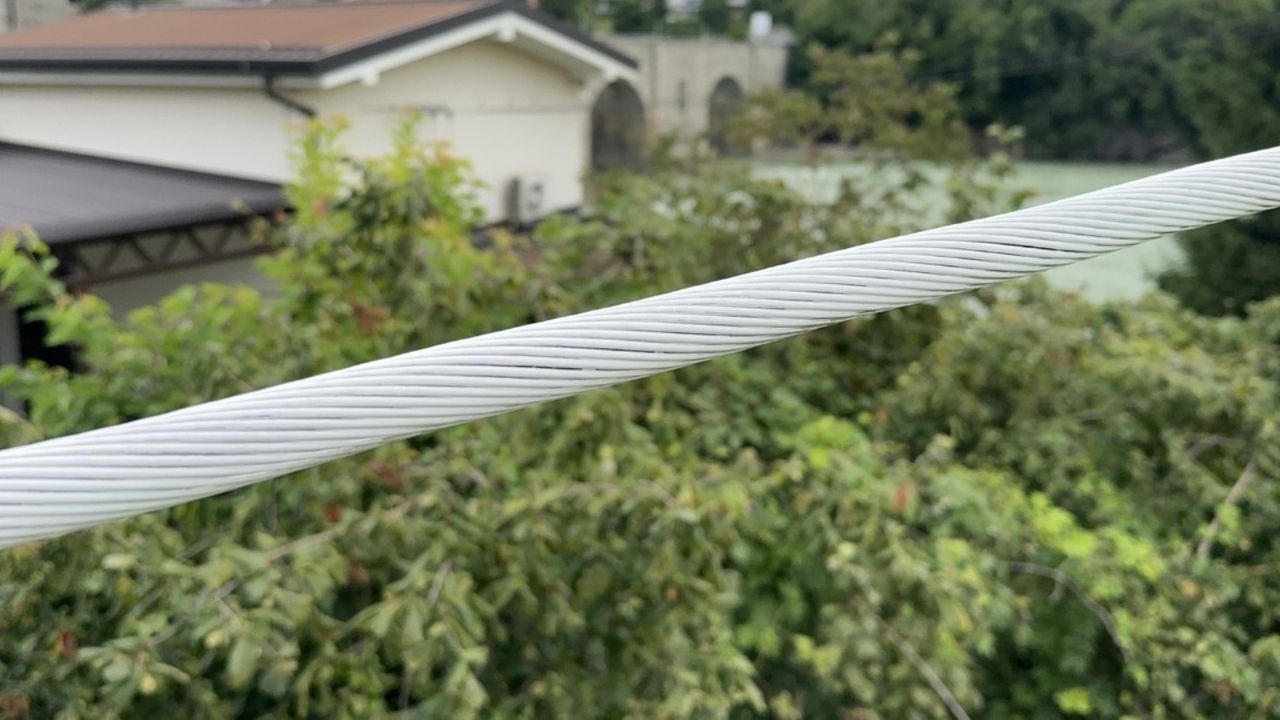

Overhead conductors have always been bare aluminium-but they don’t have to be. Many performance issues are surface-related and solvable with coatings, from solar absorption and heat dissipation to corrosion, ice build-up, and corona noise.

Material science is in our DNA.

Paired with proprietary in-situ robotic application, coating becomes a service. Utilities can now enhance capacity, tackle maintenance issues, and extend asset life, all without major engineering projects.

Power Line Coatings

Capacity Enhancement, Anti-Corrosion, Corona Noise Reduction, Ice Accretion

Innovating Today for Tomorrow’s Energy Needs.

SE01 – CAPACITY ENHANCEMENT FOR CONDUCTORS, FACTORY APPLIED

New conductors can do more from day one. Designed for factory application, SE01 features AssetCool's proprietary photonic pigmentation system, lowering conductor temperatures by 25% and boosting capacity by up to 30%.

SE02 – CAPACITY ENHANCEMENT FOR EXISTING CONDUCTORS, FIELD APPLIED

Upgrading capacity doesn’t have to mean replacing conductors. Applied directly to existing conductors, SE02’s advanced photonic coating boosts capacity by up to 30%, at just 5% of the cost of reconductoring.

SE03 - SHIELDING POWER LINES FROM CORROSION

Utilities invest heavily in corrosion surveys, often leading to an all-or-nothing choice: reconductor or leave as is. SE03 changes the equation, offering a cost-effective, in-situ solution to extend conductor life and delay costly replacements.

SE05 – CORONA NOISE MITIGATION

Rain induces “wet audible noise” which can make power line planning, voltage uprating and environmental assessments difficult without substantial line redesign. SE05’s advanced nano-coating creates a superhydrophilic surface, reducing corona noise and mitigating rain induced wet audible noise by up to 10dB.

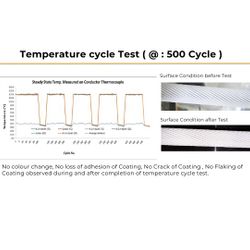

WE KNOW IT WORKS BECAUSE WE HAVE TESTED IT

AssetCool has conducted extensive field trials and testing in RSA and Saudi Arabia. These trials involved the installation of coated conductors connected in series with uncoated ones, continuously monitoring temperature variations over extended periods using K-type thermocouples.

Field Trials: Over 4 years of high-resolution field trial data

Accelerated Aging: 8000 hours of accelerated UV testing

Independent test certification

Broad environmental testing: corrosion resistance, voltage stability, mechanical stability, chemical and moisture stability.